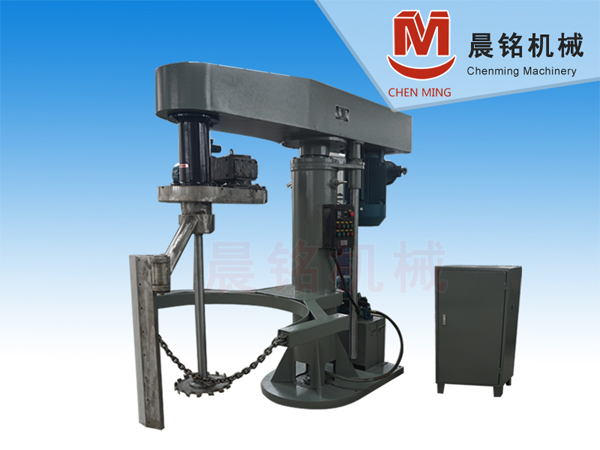

| Scraper type concentric double axis high speed dispersion machine |

F-type machines commonly used dispersion models recommended by the main paremeters:

|

Technical parameter |

F-type dispersion machine |

F250-type dispersion machine |

F350-type dispersion machine |

F450-type dispersion machine |

|

Main motor power KW |

1.5, 2.2, 3, 4 |

4, 5.5, 7.5,

6.5/8, 11, 15 |

15, 18.5, 18.5/22,

22, 30, 37, 30/42 |

45, 55, 75, 90 |

|

Decentralized shaft speed r/min |

0-1450

125-1250 |

0-1450、 125/1250

1200/2400、 1450 |

0-1450、125-1250

700/1200、1450 |

0-1450、125-1200

700/1200、1450 |

|

Pump motor power KW |

0.75 |

1.1 |

1.5 |

2.2 |

|

Lift stroke |

700 |

1000 |

1200 |

1200-2500 |

|

Disk diameter mm |

ф 150 |

ф200-250 |

ф250-350 |

ф400-550 |

|

Weight Kg |

500 |

750 |

1500 |

3000 |

|

Size length X width X height |

1000x500x1400 |

1800x750x1820 |

2200x900x2400 |

3000x1200x3200 | Main features:

The machine is high efficient equipment for the stirring, dissolution and dispersion of various mixed liquid and poweder, and is extensively applied in the production of chemical products including coating products, printing ink, dyestuff and adhesives.

Recommendation on main parameters of model selection

一.Model and adapted powers of frames

⒈Adapted power of F small frame: 1.1KW、1.5KW、2.2KW、3KW、 4KW.

⒉Adapted power of F250 frame: 4KW、5.5KW、7.5KW、 6.5/8KW、9/11KW、 11KW、15KW.

⒊Adapted power of F350 frame: 15KW、 18.5KW、 18.5/22KW、22KW、30KW、30/42KW、37KW.

⒋Adapted power of F450 frame: 45KW、 55KW、 75KW、90KW.

二.Requirements of speed:

⒈Kinds of speed: Single speed, 2-speed,3-speed,multiple speed and step-less speed change.

⒉Ways of speed change: Electromagnetic speed change, frequency-conversion speed change, decelerator speed change.

⒊Ranges of speed:125-1250r/min, 0-1450r/min, below 2000r/min, 1450r/min,2800r/min

三. Types of dispersing discs: shapes of saw-teeth, trifurcate oars, dish, frame and anchor.

四.Types of installation: F floor type, FB platform type.

五.Motors and electrical equipments: Explosion-proof(Anti-explosion)type, ordinary types.

六.Ratio of the diameter of the materials drum and diameter of dispersing disc: 3:1

七.Forms of installing the motors: Upward or downward installation of the motor output axis end. It is generally recommended to mount the output end of a motor on machines with high power downward. |

|

|